Manufacturing

Comprehensive Workshop

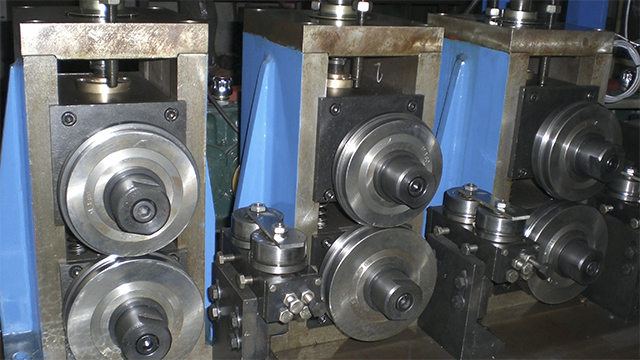

Our comprehensive workshop completes the entire manufacturing process, spanning from the initial processing and spray finishing to the final assembly. This makes production much more efficient than previously, cutting on production expenses and labor costs, thus leading to lower overall prices for the client.

The assembly workshop is the place where we conduct final assembly and then conduct a comprehensive range of operational testing. Only those equipment assemblies that have passed all tests can be shipped out of our factory.

Electrical Enclosure Production Workshop

The Electrical Enclosure Workshop is used to process and produce electrical enclosures. Our team of specialized and highly-experienced electrical engineers can help to select the most suitable electrical systems in line with the requirements of various customers.

Equipment configuration is accomplished here. According to technical drawings, Wanyi Machine combines the frequency converter, programmable logic controller (PLC), power switch and other pieces to form an entire synergistic operating system. Our equipment provides complete automatic control of all components. It operates with a human-machine interface which allows operators to set parameters with ease. All operations are conducted in an automated mode. The entire production line runs at synchronous speed. All parameters and running status are displayed on the computer. Any fault automatically triggers an alarm, immediately shutting down the equipment. Electrical engineers can provide customers with permanent electrical services.

Zhangjiagang City Wanyi Machine Factory

Add.: No.10, Lefeng Road, Zhaofeng Development Zone, Zhangjiagang City, Jiangsu Province, China

Fax: +86-512-58525318